The Secret Life of a PCB Prototype: From Sketch to Circuit

In today's technology-driven world, nearly every electronic devicefrom your smartphone to your microwaveowes its functionality to a small but mighty component: the printed circuit board, or PCB. But have you ever stopped to consider how a PCB prototype comes to life? What begins as a simple sketch on a designers notepad undergoes a fascinating transformation to become the brain behind complex electronics.

Welcome to the secret life of a PCB prototype. In this article, we take a behind-the-scenes look at the journey a PCB takes from concept to circuit, shedding light on each step in a way thats both informative and engaging. Whether you're an aspiring engineer or simply curious about what powers your gadgets, this is your comprehensive guide.

Phase 1: The Conception Ideas Take Shape

Every PCB prototype begins with a problemor more accurately, the solution to a problem. Engineers and product designers identify the need for a new electronic device or improvement in existing technology. From this seed, ideas are brainstormed, and functional requirements are jotted down.

At this stage, there is no copper or silicon in sight. Instead, what youll find are block diagrams, hand-drawn circuits, and lots of coffee-fueled discussions. Designers typically use software such as Altium Designer, Eagle, or KiCad to create initial schematics. These digital blueprints define how each component will interact on the board.

If you want to find out more about the tools used in this early stage, numerous tutorials and forums offer deep dives into schematic capture techniques.

Phase 2: Schematic Design Laying the Foundation

Once the concept is clear, the real work begins. The schematic design is the technical drawing of the entire electronic system. It includes resistors, capacitors, microcontrollers, connectors, and every other component needed to fulfill the circuits function.

Each of these components is connected by virtual lines that represent electrical connections. This schematic acts like a city map, showing the flow of electricity through each "street" and "neighborhood." Any mistake at this stagelike misconnecting a capacitor or leaving out a resistorcan doom the entire prototype.

Engineers spend considerable time reviewing and simulating their schematics to ensure every aspect is accurate. This is where the circuit begins to evolve from theory into a tangible, working model.

Phase 3: PCB Layout Turning 2D into 3D

After the schematic is perfected, the next step is translating that 2D plan into a 3D physical layoutthe actual PCB prototype. This is a highly detailed process that involves arranging the components on a board and routing the copper traces that will carry signals between them.

The layout must be carefully optimized to ensure minimal electrical noise and maximum efficiency. Factors like board size, thermal management, and electromagnetic interference all come into play. Engineers also need to consider manufacturabilitymaking sure the board can actually be produced without errors.

At this point, its not uncommon to check over here for design rule checks (DRC) and electrical rule checks (ERC), automated processes that validate your design against industry standards and project-specific constraints.

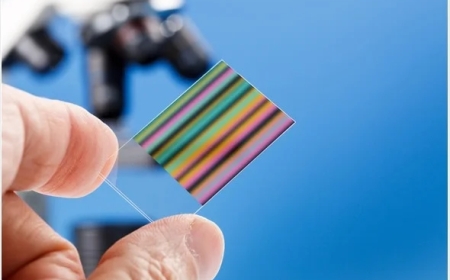

Phase 4: Fabrication From Design to Reality

With the design locked down, its time to bring the PCB prototype into the real world. Fabrication is the process of creating the physical board based on your digital design files.

Heres what happens:

- Substrate Creation: Typically made from fiberglass (FR4), this non-conductive layer serves as the base.

- Copper Layering: Thin layers of copper are laminated onto the substrate.

- Photoresist Application: A light-sensitive film is applied, which helps define the copper pathways.

- Etching: Chemical solutions remove unwanted copper, leaving only the desired circuit paths.

- Drilling & Plating: Holes are drilled for through-hole components, and copper is plated in them to allow electrical connectivity.

- Solder Mask & Silkscreen: The board is coated to protect it from oxidation and labeled for assembly.

This manufacturing process requires incredible precision. Even the tiniest error can render a PCB prototype useless. If you're curious about how factories manage such tight tolerances, go right here to explore a range of resources on industrial fabrication techniques.

Phase 5: Assembly Bringing the Circuit to Life

Fabricated PCBs are lifeless without components. The assembly stage involves placing and soldering components onto the board. This can be done manually for small batches or via automated pick-and-place machines for larger productions.

Surface-mount technology (SMT) is the most common method, where components are mounted directly onto the surface of the PCB. After placement, the board passes through a reflow oven to melt the solder and secure the parts.

Quality assurance is crucial. Engineers often use optical inspection, X-ray analysis, and functional testing to ensure the assembled PCB meets all specifications. This stage is often repeated in iterative cycles, especially in prototype development, to iron out bugs and improve performance.

Phase 6: Testing Making Sure It Works

The PCB prototype may look ready, but appearances can be deceiving. Rigorous testing must be performed to verify functionality, signal integrity, and thermal performance. Engineers run simulations and real-world scenarios to stress-test the board.

Common tests include:

- Continuity Testing: Verifies that electrical paths are correctly connected.

- Functional Testing: Ensures the circuit performs its intended role.

- Environmental Testing: Subjects the board to temperature extremes and humidity to assess durability.

If issues are discovered, the prototype goes back to the design phase for adjustments. This cyclical nature of design, test, and refine is what ensures a robust final product.

Conclusion:

From its humble beginnings as a sketch to a fully functional circuit, the life of a PCB prototype is a testament to the intricate dance between creativity and engineering. Each stepconception, design, fabrication, assembly, and testingis vital and interdependent.

For engineers, the process of developing a PCB prototype is not just a technical challengeits a craft. And for consumers, understanding this journey adds a new layer of appreciation to the electronics we often take for granted.

Want to find out more about how to start your own PCB design project? Whether youre a student or a seasoned professional, the path begins with a simple ideaand the willingness to bring it to life, one trace at a time.