Precision Unleashed: The Power and Potential of CNC Sheet Metal Cutting in Modern Fabrication

Experience unmatched precision and speed with CNC sheet metal cutting—ideal for industrial, architectural, and high-performance fabrication needs.

In today's fast-paced industrial world, the demand for precise, efficient, and cost-effective fabrication solutions has never been higher. As industries continue to evolve, so do the methods used to shape the materials that support them. One standout advancement that has redefined the standards of modern manufacturing is CNC sheet metal cutting. This technology has transformed how engineers, architects, and manufacturers approach design, prototyping, and productiondelivering superior accuracy, speed, and flexibility.

Traditional sheet metal cutting methods, though reliable in certain applications, often fall short in meeting the stringent tolerances and customization needs of contemporary projects. With the rise of automation and digital integration, fabricators are turning to CNC Sheet metal cutting to execute highly detailed cuts with unmatched precision. This computer-controlled process ensures consistency across high-volume production runs while enabling the fabrication of complex geometries that were once impractical or time-consuming.

What Is CNC Sheet Metal Cutting?

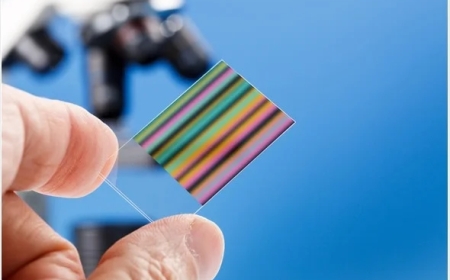

CNC (Computer Numerical Control) sheet metal cutting refers to the automated process of cutting metal sheets using computer-guided tools. The system reads digital blueprintstypically from CAD (Computer-Aided Design) softwareand translates them into precise cutting instructions. Machines such as laser cutters, plasma cutters, and waterjet systems then execute the cuts with incredible speed and accuracy.

The automation involved in CNC systems reduces the need for manual labor while significantly improving output quality. Since the process is digitally controlled, there is minimal room for human error, leading to clean edges, tight tolerances, and consistent results. Whether working with stainless steel, aluminum, brass, or galvanized steel, CNC machines can adapt to a wide range of materials and thicknesses, making them ideal for both industrial and architectural applications.

Advantages Over Traditional Cutting Methods

One of the most significant advantages of CNC sheet metal cutting is the precision it offers. Unlike manual cutting tools, CNC machines deliver consistent results down to fractions of a millimeter, even on complex shapes. This level of accuracy is essential in industries like aerospace, medical device manufacturing, and electronics, where even the slightest deviation can compromise performance or safety.

Speed is another critical benefit. CNC machines operate at high speeds without sacrificing accuracy, enabling faster turnaround times. Moreover, because the machines can be programmed to perform repetitive tasks, production becomes more scalable without a dip in quality. This makes CNC cutting not only efficient but also cost-effective over time.

The reduction of material waste is also a notable benefit. CNC systems optimize cutting paths to make the most of each sheet, minimizing scrap and contributing to sustainable fabrication practices. This efficiency directly translates into lower material costs and supports environmentally conscious production goals.

Key Industrial Applications

CNC sheet metal cutting plays a vital role in many industrial sectors. In the automotive industry, it is used to manufacture everything from chassis parts and body panels to brackets and engine components. These parts must meet tight tolerances to ensure structural integrity and safety, making CNC cutting indispensable.

In aerospace, lightweight yet strong components are cut with high precision to withstand the stresses of flight. Fabricators can produce intricate shapes and internal cutouts with minimal heat distortion, which is crucial in sensitive engineering environments. Likewise, the electronics sector benefits from CNCs ability to cut small, detailed enclosures and brackets that fit compact circuit boards and assemblies.

Energy, agriculture, and heavy machinery industries also rely on CNC cutting to produce structural parts, support frames, and enclosures that require both durability and exacting design.

Architectural and Decorative Uses

Beyond industrial applications, CNC sheet metal cutting has opened new doors in architectural design. Architects and designers now use CNC technology to craft decorative panels, faades, balustrades, partitions, and signage with intricate patterns and customized dimensions. Because the process can handle both functional and aesthetic tasks, it is widely used in commercial interiors, hospitality design, and public installations.

Architectural metalwork often requires not only precision but also a flawless finish. CNC cutting ensures edges are smooth and components fit seamlessly into the overall structure. This is especially beneficial for high-end applications, such as luxury interiors, custom staircases, and modern cladding systems.

Moreover, CNC allows for experimentation with materials and patterns that were previously impossible with manual tools. Designers can push creative boundaries while ensuring the final product is consistent, safe, and visually compelling.

Customization and Flexibility

Another key strength of CNC sheet metal cutting is its exceptional flexibility. Because the process is digitally driven, fabricators can quickly switch between different designs, part geometries, and production volumes without extensive retooling. This is especially valuable in projects requiring frequent revisions or limited-run production.

Custom parts, prototypes, and one-off designs can be manufactured with the same precision as high-volume components. Additionally, CNC systems support a variety of cutting technologies, each suited to specific taskslaser cutting for ultra-fine details, plasma cutting for thicker metals, and waterjet cutting for materials sensitive to heat.

Thanks to CAD/CAM (Computer-Aided Manufacturing) software, designers and engineers can collaborate efficiently. A change made in a digital file can be directly implemented on the machine, reducing lead times and streamlining the development cycle.

Future Trends in CNC Metal Cutting

As industries continue to adopt smart manufacturing practices, CNC sheet metal cutting is evolving alongside digital technologies. One significant trend is the integration of AI and machine learning. These tools help optimize tool paths, monitor machine health, and predict maintenance needs, reducing downtime and boosting efficiency.

The rise of the smart factory is also reshaping how fabrication facilities operate. CNC machines are increasingly connected to centralized platforms that monitor real-time production metrics, inventory levels, and job progress. This integration improves decision-making and supports lean manufacturing principles.

Sustainability is another driving force. Many CNC systems now feature energy-efficient motors and low-waste processing, which supports environmentally responsible production. Paired with recyclable sheet metals like aluminum and stainless steel, CNC cutting helps reduce the carbon footprint of manufacturing operations.

As 3D printing and additive manufacturing become more widespread, hybrid systems that combine CNC and additive processes are emerging. These platforms can fabricate complex base parts with additive methods and refine them with CNC cutting, offering new possibilities for part design and production.

Conclusion

CNC sheet metal cutting has become a cornerstone of modern fabrication, empowering industries to meet the growing demand for precision, customization, and efficiency. From aerospace components to decorative architectural features, this technology delivers high-quality results with minimal waste and maximum repeatability.

Its integration with digital design tools and smart factory systems continues to push the boundaries of whats possible in manufacturing. By offering unparalleled accuracy, reduced turnaround times, and cost-effective production, CNC cutting not only supports current needs but also prepares industries for future challenges.

Whether you're building robust industrial systems or creating elegant architectural installations, CNC sheet metal cutting is a powerful tool that brings ideas to life with precision and performance. As innovation drives manufacturing forward, CNC will remain at the forefrontwhere precision truly is unleashed.