Cybersecurity Considerations in Digitized Cable Factories

Explore critical cybersecurity considerations for digitized cable factories, addressing threats to OT and IT systems, and outlining strategies for a robust defense.

The modern cable factory is a technological marvel. Gone are the days of purely mechanical, isolated machines. Today's facilities are increasingly "smart," powered by Industry 4.0 principles, with interconnected machinery, IoT sensors, robotics, and data analytics platforms all working in concert. This digital transformation unlocks incredible gains in efficiency, quality, and agility. However, this increased connectivity also opens a new and critical front: cybersecurity. As we connect our factory floors to our corporate networks and the internet, we must address the significant cybersecurity considerations to protect our operations, data, and people from emerging digital threats.

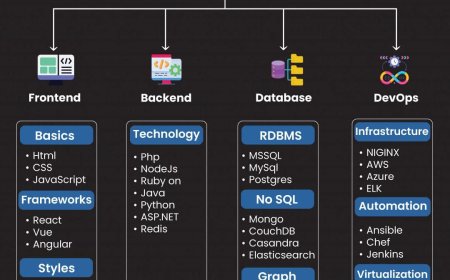

The Two Worlds of Factory Cybersecurity: IT vs. OT

To understand the risks, it's crucial to distinguish between two interconnected domains:

-

Information Technology (IT): This is the world of business systems email servers, ERP systems, company websites, laptops, and corporate networks. The primary goals of IT security are confidentiality, integrity, and availability of data.

-

Operational Technology (OT): This is the world of the factory floor the hardware and software that controls physical processes. This includes Programmable Logic Controllers (PLCs) running machines, Human-Machine Interfaces (HMIs), industrial control systems (ICS), SCADA systems, and robots. The primary goals of OT security are the availability, safety, and integrity of physical operations. An OT failure means machines stop, production halts, and physical safety can be compromised.

Historically, OT networks were "air-gapped" physically isolated from IT networks and the internet. In today's digitized factories, these worlds are converging, creating new pathways for cyber threats to move from the digital realm to the physical factory floor.

Potential Cyber Threats Facing a Cable Factory

What are the specific risks that a digitized cable manufacturer, whether in India or elsewhere, needs to consider?

-

Ransomware Attacks: A malicious actor could gain access to the network and encrypt critical systems not just business servers (IT), but potentially manufacturing execution systems (MES) or even machine controllers (OT) demanding a ransom to restore operations. This could shut down the entire plant.

-

Industrial Espionage: Competitors could attempt to steal sensitive intellectual property, such as proprietary polymer formulas, unique cable designs, or detailed manufacturing process parameters.

-

Production Sabotage: A sophisticated attacker could subtly alter machine parameters (e.g., changing the temperature on an extruder, slowing a take-up reel). This might not cause an immediate shutdown but could lead to the production of low-quality, out-of-spec cable that fails in the field, causing immense reputational and financial damage. This is a particularly insidious threat.

-

Denial-of-Service (DoS) Attacks: Overwhelming the factory network with traffic, potentially making it impossible for controllers and sensors to communicate, leading to a disorderly shutdown.

-

Safety System Compromise: An attacker could potentially disable critical safety systems (like emergency stops or pressure sensors), creating a direct physical danger to workers.

-

Supply Chain Attacks: A compromise at a trusted third-party vendor or a supplier, like one of the quality cable suppliers in uae, could potentially be used as an entry point into the manufacturer's network.

Building a Strong Defense: Key Cybersecurity Strategies

Protecting a digitized factory requires a multi-layered, "defense-in-depth" approach:

1. Network Segmentation & Segregation

This is a foundational principle. Don't have one flat network where everything can talk to everything else.

-

IT/OT Separation: Create a secure buffer zone (often called a DMZ - Demilitarized Zone) between the business (IT) network and the factory floor (OT) network. All traffic between these two zones must be strictly controlled and monitored.

-

Micro-segmentation: Within the OT network, further divide it into smaller zones. For example, the extrusion line might be in one segment, and the wire drawing area in another. This contains the impact of a breach; if one segment is compromised, it's much harder for the attacker to move to another.

2. Access Control & Authentication

-

Principle of Least Privilege: Users and devices should only have access to the data and systems they absolutely need to perform their jobs. An operator on Line 1 should not be able to access the controls for Line 2.

-

Strong Passwords & Multi-Factor Authentication (MFA): Enforce strong password policies for all systems. Use MFA wherever possible, especially for remote access or access to critical systems.

-

Secure Remote Access: If vendors or remote employees need to access factory systems, use secure, controlled methods like VPNs with strict access controls, rather than leaving ports open to the internet.

3. Continuous Monitoring & Threat Detection

-

Network Visibility: Deploy tools that provide continuous visibility into the OT network. You need to know what devices are on your network and what they are communicating.

-

Intrusion Detection Systems (IDS): Use specialized industrial IDS that can understand OT protocols (like Modbus, Profinet) to detect anomalous or malicious traffic patterns specific to the factory floor.

-

Log Management: Collect and analyze logs from network devices, servers, and machine controllers to spot signs of suspicious activity.

4. System Hardening & Patch Management

-

Disable Unused Ports/Services: Turn off any unnecessary physical ports on switches or network services on controllers to reduce the attack surface.

-

Regular Patching: This is a major challenge in OT environments, as patching a controller can require shutting down a production line. A risk-based approach is needed, where critical security patches are tested in a lab environment before being carefully scheduled for deployment.

5. Employee Training & Awareness

-

The "human firewall" is crucial. Conduct regular training for all employees on cybersecurity best practices, such as identifying phishing emails, using strong passwords, and understanding the importance of physical security (e.g., not plugging unauthorized USB drives into factory equipment).

6. Incident Response Planning

-

Have a plan before an incident happens. Who do you call? How do you isolate affected systems? How do you restore operations safely? Regularly test this plan with drills and tabletop exercises. This level of planning is a key part of the operational excellence demonstrated by top-tier cable manufacturers in uae.

Conclusion: Securing the Future of Cable Manufacturing

The digitization of cable factories offers immense rewards, but it comes with inherent responsibilities. Cybersecurity can no longer be an afterthought or solely the domain of the IT department. It must be a core consideration in the design, implementation, and operation of any smart manufacturing initiative, with close collaboration between IT and OT teams. By adopting a robust, multi-layered security posture focusing on network segmentation, strict access control, continuous monitoring, and employee awareness cable manufacturers can safely harness the power of digital transformation, protecting their operations from emerging threats and securing their place as leaders in the industry.

Your Factory Cybersecurity Questions Answered (FAQs)

-

What is the single biggest cybersecurity risk to a factory?

While ransomware gets a lot of headlines due to its disruptive nature, a subtle, undetected attack that manipulates the production process (e.g., slightly altering cable quality) can be just as damaging in the long run, causing massive reputational harm and recall costs. Both are significant risks. -

Why can't we just use the same antivirus software on factory machines as we do on office PCs?

Industrial control systems (like PLCs) often use real-time operating systems and specialized hardware that are not compatible with standard antivirus software. Furthermore, running a scan could consume too many resources and interfere with the time-critical control tasks, potentially causing a machine to malfunction. OT security requires specialized tools. -

What does "air-gapped" mean and is it still a valid strategy?

"Air-gapped" means a network is physically isolated with no connection to any other network, especially the internet. While it provides strong security, it is becoming increasingly impractical for smart factories that rely on data sharing for analytics, remote monitoring, and supply chain integration. The modern approach is secure, controlled connectivity, not total isolation. -

Who is responsible for OT cybersecurity the IT team or the engineering team?

It must be a collaborative effort. The IT team brings deep expertise in networking, firewalls, and general cybersecurity practices. The OT (engineering) team understands the industrial processes, the control systems, and the critical need for operational uptime and safety. Successful OT security programs require both teams to work together closely. -

How do we secure older, "legacy" equipment that was never designed for network connectivity?

Securing legacy equipment is a major challenge. The primary strategy is "compensating controls." Since you can't install security software on the device itself, you protect it by isolating it on a secure network segment, placing a firewall in front of it to strictly control traffic, and monitoring its network activity for any suspicious behavior.